Hot stamping holographic foil

Holographic Hot Stamping Foil is unique means of protection against forgery of documents, packaging and printing products.

Hot Stamping Foil for a long time and is widely used in printing industry for finishing processes, first of all for the gold emboss of expensive books bindings. This process is made at special presses, which are called "gilding". While embossing, lacquer metallized layer moves from the basics of foil to paper. The foil has complex structure of multiple layers deposited to a thin (12-23 microns) polyester base. In general, foil structure is similar to the structure of the material for decomposable holograms, but instead of non-drying adhesive layer there applied a special glue, which dries and ceases to be tacky at room temperature. While embossed it softens and is pressed into the paper with hot metal. When the stamp moves away from paper, glue cools and hardens, so that when it separates from the paper again, varnish layer remains on it. If the stamp is shaped, then the "gilded" the image of the stamp remains at the paper.

The difference of holographic foil from usual metallized one is the presence of micro-relief on the metallized layer. To create this micro-relief, there is done embossment (lamination)of foil at high pressure by hot-nickel matrix. In this process the varnish layer is to stay on the base. Thus, in one process - lamination – the separating layer should keep the varnish layer and in the other - embossment - to release it. To meet these conflicting demands it is necessary to design and select the separation layers very carefully, what makes holographic foil much more expensive product than the usual hot stamping holographic foil.

The embossment process here is more difficult. The important parameter is the quality of the paper at which the foil pressed. If the paper has a smooth glossy layer (coated paper), the problems tend to arise. However, if the paper has a rough or fibrous structure (for example, cotton paper or paper with water marks), then this structure is partly manifested in the form of microscopic irregularities on the reflecting layer, which leads to deterioration of the light scattering and holographic images.

If it strongly affects the quality of the image, one has to use supplementary means of paper surface preparation or pick up special adhesives.

Another problem is the so-called ‘registration’ of a holographic image. The point is that the hologram at the foil can be made either in a continuous pattern way (so-called foil «wallpaper» - Wallpapers, when it does not matter where the foil is stamped, either in the form of specific image (for example logo), and in this case the stamp should fall exactly on the holographic image. for such a precise hit, the eye mark is made next to hologram and it is read by special sensors. Usual foil stamping doesn’t require register, so the ordinary gilding presses are not equipped with such sensors. Due to complexity of the process, the cost of stamping register holograms may be higher than the cost of the hologram itself. Therefore register holograms are pressed either to important documents, which requires a specific pictorial representation, or to the packaging of products whose price is much higher than the cost of the package itself.

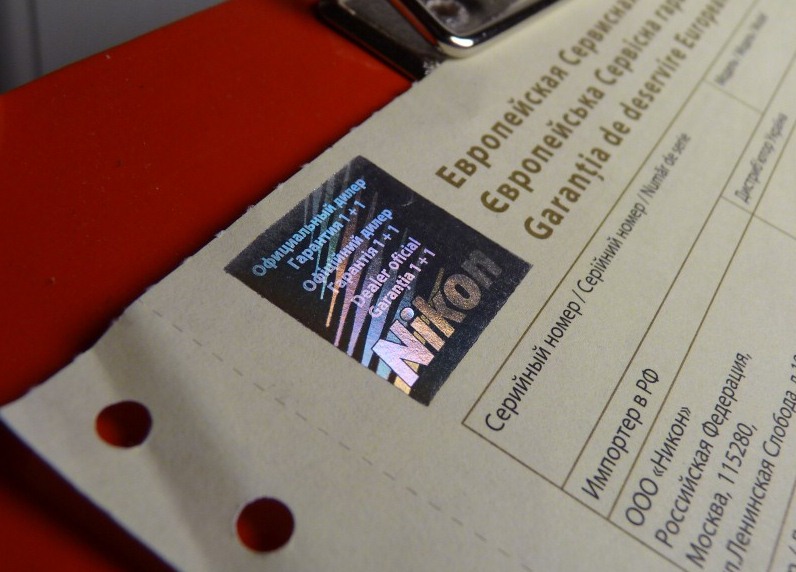

And, perhaps, the main difference of pressed hologram from a sticker is that it is almost impossible to separate it from the paper without destruction and move it to another document. So, these holograms are often used for protection against paper documents forgery.